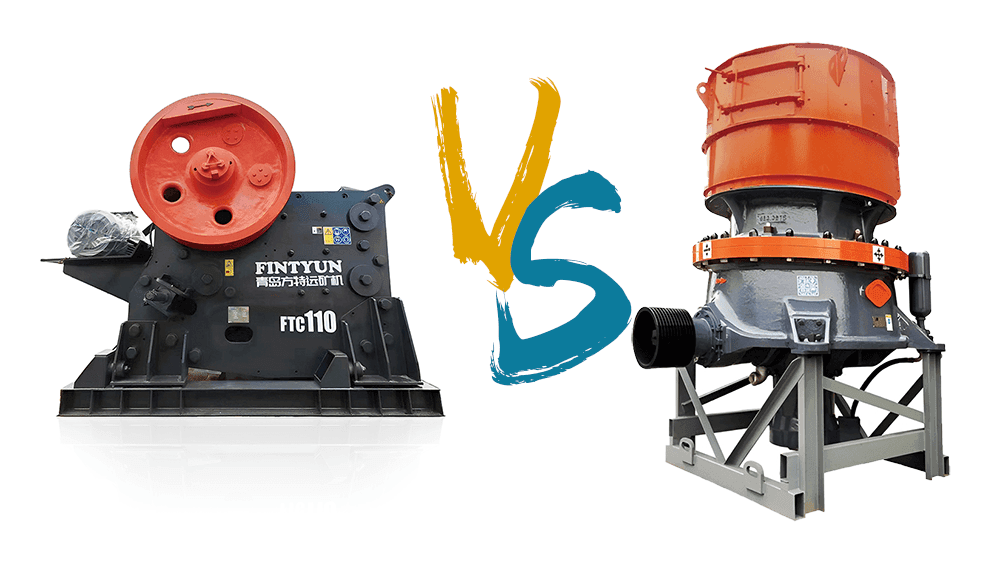

Щелковая и Конусная дробилки — распространённое дробильное оборудование, но чем они отличаются? Какую из них выбрать? Давайте рассмотрим их различия и преимущества.

Сравнение щелковой дробилки с конусной дробилкой

Щелковая дробилка в первую очередь осуществляет первичное дробление, разбивая крупные камни (до 1500 мм) на более мелкие куски (менее 100 мм) для дальнейшей обработки.

Конусная дробилка, в свою очередь, дробит камни среднего размера и в основном выполняет функцию вторичного дробления. Она специализируется на дроблении твёрдых камней и оснащена предохранительным механизмом, который срабатывает для защиты оборудования от повреждений.

Основные различия между щелковой и конусной дробилкой

Знание этих различий поможет вам выбрать наиболее подходящий вариант.

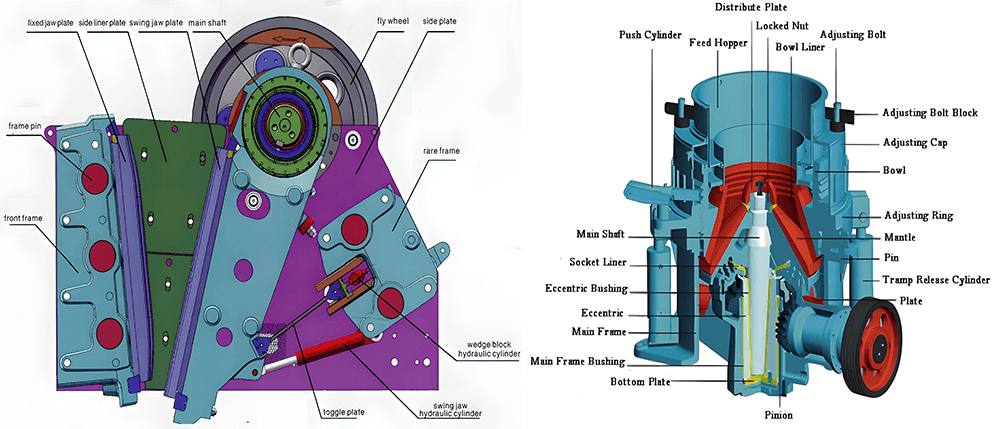

1. Общая структура: щелковая дробилка VS конусная дробилка

Щелковая дробилка:

- Она состоит из рамы, передаточного механизма, регулировочного устройства, натяжного устройства, предохранительного устройства и системы смазки.

- Передаточный механизм соединяет всю конструкцию и играет ключевую роль.

- Он использует сжимающее усилие для эффективного дробления твёрдых камней с высокой степенью дробления.

Конусная дробилка:

- Состоит из рамы, гидравлических компонентов, головки, кожуха, главного вала, промежуточного вала, подающей плиты, опорного кольца, гнезда, эксцентрика, шестерни и т.д.

- Основными износостойкими деталями являются дробящие стенки.

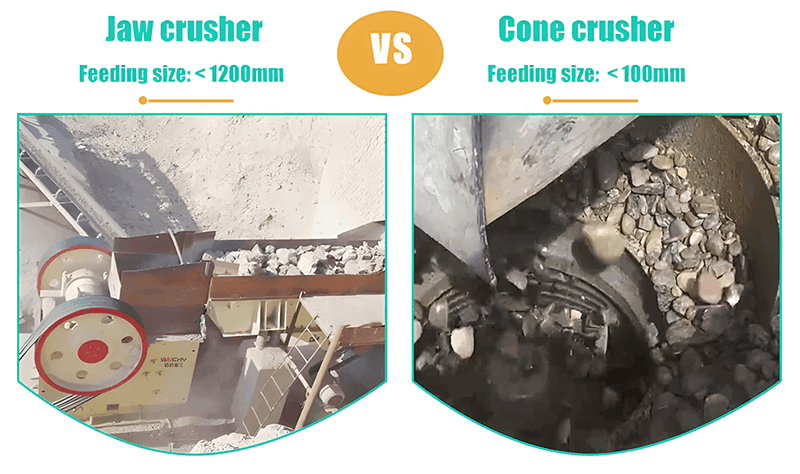

2. Требования к подаче: щелковая дробилка VS конусная дробилка

Щелковая дробилка:

- Обрабатывает широкий диапазон размеров исходного материала.

- Большие щековые дробилки работают с материалом крупностью более 600 мм (до 1200 мм), средние — с материалом 300–600 мм, а малые — с материалом менее 300 мм.

Конусная дробилка:

- Требует меньшего размера исходного материала, обычно менее 450 мм (зависит от модели).

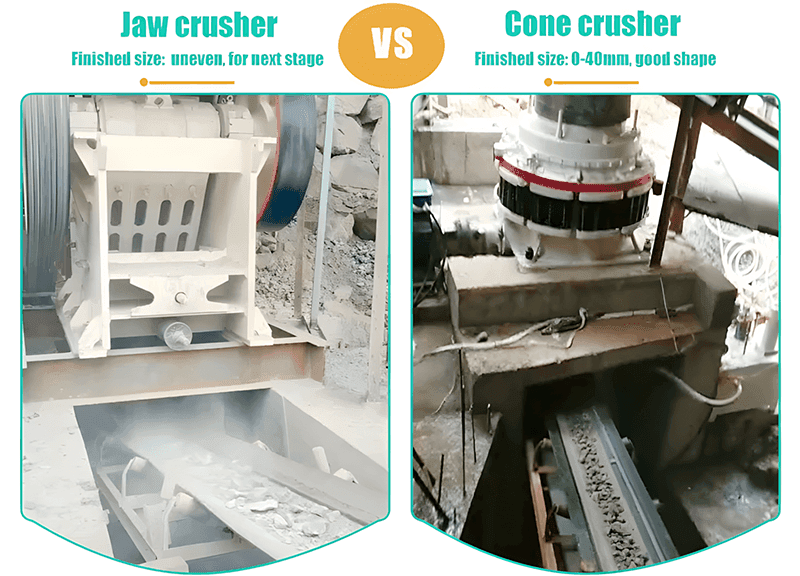

3. Форма готового продукта

Щелковая дробилка:

- Идеально подходит для первичного дробления, обеспечивая высокую производительность и более крупные размеры выходного материала.

- При необходимости также подходит для вторичного дробления.

Конусная дробилка:

- Она обеспечивает вторичное и третичное дробление, образуя более мелкие частицы однородной формы.

- Непрерывно измельчает материал до тех пор, пока он не пройдет через узкое разгрузочное отверстие.

4. Сравнение цен

Из-за сложной конструкции и износостойких деталей конусная дробилка стоит значительно дороже щековой.

- Объем конусной дробилки в 2-3 раза выше щековой.

- При равной производительности конусная дробилка весит в 1-2 раза тяжелее.

- Ее монтаж и обслуживание также сложнее.

5. Пример: сравнение дробилок производительностью 300 тонн в час

При сравнении установок производительностью 300 тонн в час:

- Конусная дробилка весит примерно вдвое больше щековой, что увеличивает затраты на строительство и обслуживание.

- Щелковые дробилки обеспечивают более высокую степень дробления, тогда как конусные дробилки более эффективно обрабатывают твердые материалы.

| Model | Jaw Crusher | Cone Crusher |

|---|---|---|

| Max feed size | 630 mm | 215 mm |

| Output size | 60-150 mm | 25-60 mm |

| Capacity | 110-380 TPH | 180-360 TPH |

| Motor power | 110 kW | 160 kW |

| Weight | 29 tons | 60 tons |

Заключение

Как щелковые, так и конусные дробилки обладают уникальными преимуществами. Щелковые дробилки превосходны на первичном дроблении благодаря высокой производительности, в то время как конусные дробилки обеспечивают более мелкий выход на вторичной и третичной стадиях дробления. Выбор зависит от твёрдости материала, желаемого размера выходного материала, производственных потребностей и бюджета. Перед покупкой проконсультируйтесь со специалистом для получения профессиональной консультации.

Часто задаваемые вопросы (FAQ)

В: Какой тип дробилки лучше — конусная или щелковая?

О: Щелковые дробилки обрабатывают камни от мягкого известняка до твёрдого гранита, а конусные дробилки используют вращающийся конус для более тонкого дробления.

В: Зачем использовать конусную дробилку?

О: Они эффективно перерабатывают породы средней и высокой твёрдости, потребляя меньше энергии, сохраняя высокую надёжность и обеспечивая значительное измельчение.

В: Насколько тонко дробит конусная дробилка?

О: Конусные дробилки обычно перерабатывают материалы предварительно заданного размера (100–200 мм) в более мелкие, хорошо рассортированные материалы.

В: Какая дробилка лучше всего подходит для камня?

О: Выбор оптимальной дробилки зависит от твёрдости материала, требуемого размера выходного материала и производственных потребностей. Доступны щелковые, конусные, ударные, валковые, молотковые, дробилки с вертикальным валом (VSI) и мобильные дробильные установки.

В: Каковы преимущества конусных дробилок?

О: Конусные дробилки обеспечивают высокую эффективность, равномерный размер частиц, низкое энергопотребление и надёжную работу. Они отлично справляются со вторичным и третичным дроблением, хорошо справляются с твердыми материалами и оснащены встроенной защитой от перегрузки.

В: Каков принцип работы конусной дробилки?

О: Конусная дробилка работает, сжимая материал между вращающейся конусной плитой и неподвижной вогнутой подушкой. Эксцентриковое движение создаёт сжатие, дробя горную породу на более мелкие, равномерно распределенные частицы.

В: Используются ли конусные дробилки для первичного дробления?

О: Обычно нет — конусные дробилки в основном предназначены для вторичного/третичного дробления. Однако некоторые модели (например, дробилка CC400S) могут использоваться для первичного дробления в особых случаях.

В: Какая дробилка лучше всего подходит для твёрдых пород?

О: Для твёрдых пород (например, гранита, базальта) идеально подходят щековые дробилки (первичное дробление) и конусные дробилки (вторичное дробление). Высокая степень измельчения и высокая сила сжатия конусных дробилок делают их особенно эффективными.

В: Почему именно щелковые дробилки?

О: Щелковые дробилки экономичны, просты в обслуживании и универсальны для первичного дробления. Они способны обрабатывать крупные куски исходного материала (до 1500 мм) и прочные материалы, что делает их идеальным решением для первичного дробления горных пород.

В: Как обслуживать конусную дробилку?

О: Регулярно проверяйте смазку (уровень масла/фильтры), осматривайте изнашиваемые детали (подвижный / неподвижный конуса), следите за натяжением ремня и очищайте от пыли/мусора. Планируйте время простоя для замены футеровки и проверки центровки, чтобы предотвратить поломки.