Описание

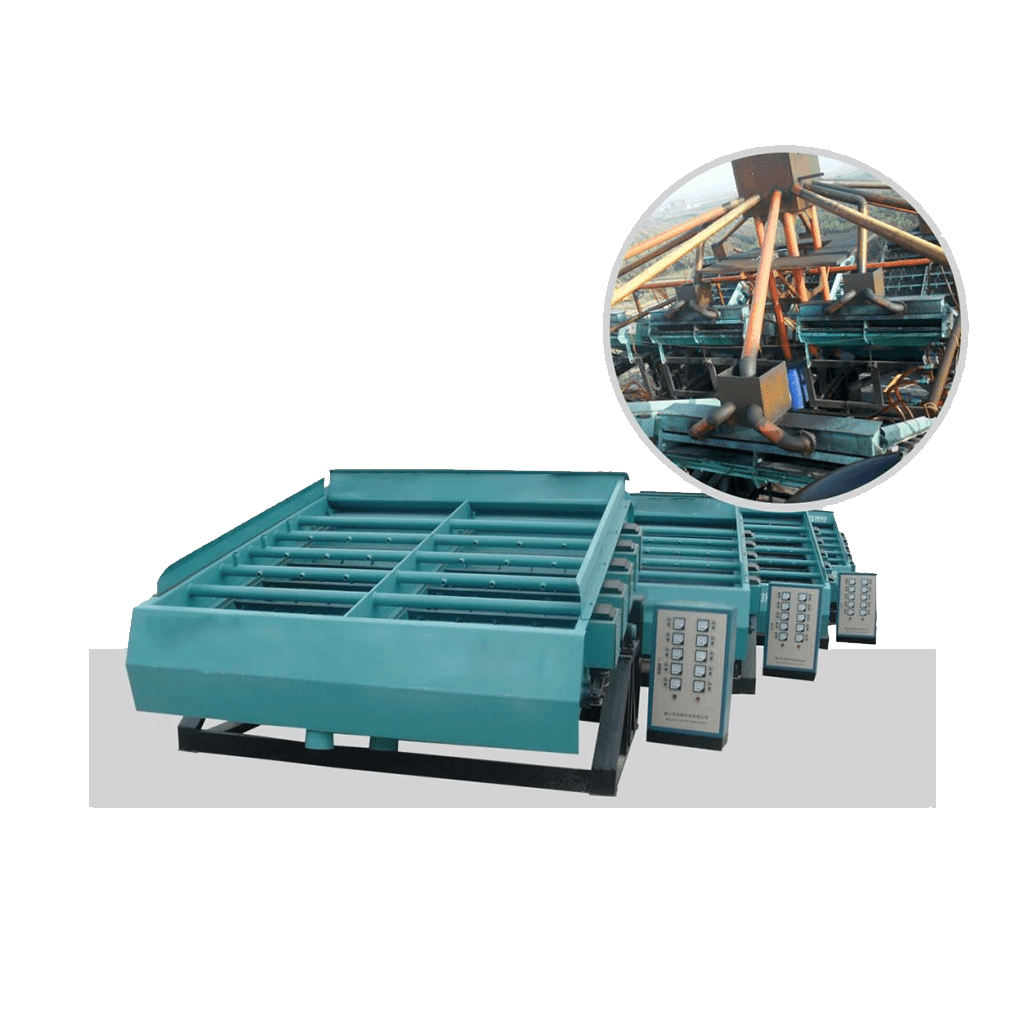

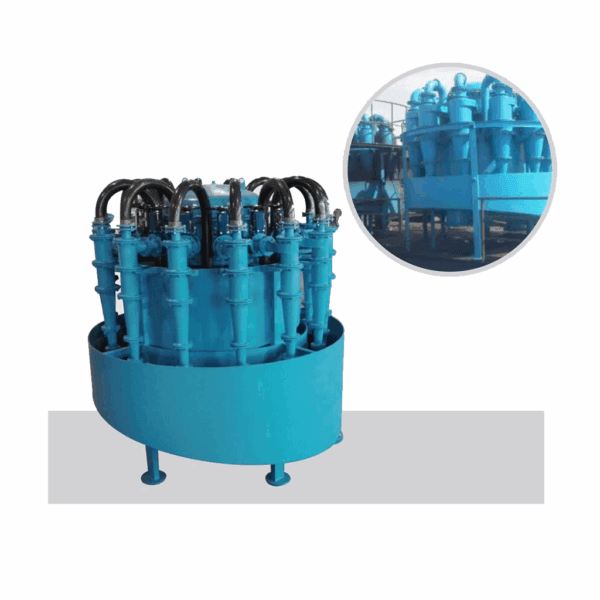

Вибрационный грохот серии CNC – Гид

CNC вибрационный грохот работает по принципу электромагнитного возбуждения колебаний: поверхность грохота вибрирует, а весь короб грохота остается неподвижным. Низкий уровень вибрации и низкое энергопотребление.

Сила вибрации высокая (в 8-10 раз превышает ускорение свободного падения), процент просеивания на 10-50% больше, чем у обычных грохотов, эффективность просеивания выше, производительность больше.

Ситовая поверхность представляет собой трехъярусную сетку: верхний ярус, выполняющий просеивание, изготовлен из двухъярусной композитной сетки, плетеной из стальной проволоки, а нижний ярус, соединенный с вибрирующим рычагом, изготовлен из полиуретановой опорной сетки со стальной проволокой.

Применяется для классификации, обезвоживания и обесшламливания мелкодисперсных материалов и т. д. и широко применяется в обогащении полезных ископаемых, угольной промышленности, производстве строительных материалов, химической промышленности и т. д.

Технические данные вибросита CNC

1. Обзор продукта

Вибросито CNC обеспечивает точное разделение материалов. Мы разрабатываем современные грохоты для горнодобывающей промышленности. В этом оборудовании используется технология электромагнитных колебаний. Поверхность грохота движется, а рама остается неподвижной. Оно эффективно работает с мелкими материалами.

2. Основные характеристики

- Высокая сила вибрации (8-10 G)

- Высокая эффективность просеивания

- Низкое энергопотребление

- Минимальная вибрация рамы

- Трехслойная сетка грохота

- Высокая производительность

- Прочность конструкции

3. Принцип работы

- Электромагнитная система создаёт вибрацию

- Поверхность сита быстро движется

- Материалы разделяются по размеру

- Мелкие частицы проходят

- Выгрузка крупных частиц

- Процесс продолжается автоматически

4. Основные компоненты вибросита CNC

Поверхность сита

- Трёхслойная конструкция

- Верхний слой: стальная проволочная сетка

- Средний слой: композитная сетка

- Нижний слой: полиуретановая основа

- Высокая износостойкость

Электромагнитная система

- Создаёт вибрацию

- Точное управление

- Регулируемая интенсивность

- Энергоэффективность

- Надежная работа

Корпус грохота

- Устойчивая конструкция

- Отсутствие передачи вибрации

- Устойчив к коррозии

- Простота обслуживания

- Функции безопасности

Разгрузочные желоба

- Разделение потоков материала

- Регулируемые углы наклона

- Износостойкая футеровка

- Плавный выход материала

5. Руководство по установке

- Подготовьте ровное основание

- Правильно установите грохот

- Подключите питание

- Установите загрузочный желоб

- Настройте разгрузочные желоба

- Проверьте все крепления

- Проверьте работу

6. Советы по эксплуатации

- Контролируйте скорость подачи

- Контролируйте интенсивность вибрации

- Проверяйте состояние ячеек грохота

- Следите за распределением материала

- Регулярно очищайте

- Смазывайте подшипники

- Записывайте данные о производительности

7. График технического обслуживания

- Ежедневный визуальный осмотр

- Еженедельная затяжка болтов

- Ежемесячная очистка сетки

- Ежеквартальная проверка подшипников

- Ежегодное полное обслуживание

8. Распространенные проблемы

Проблема: Снижение эффективности

Решение: Очистка сетки

Проблема: Неравномерная вибрация

Решение: Проверка электромагнитной системы

Проблема: Накопление материала

Решение: Отрегулировать скорость подачи

Проблема: Громкий шум

Решение: Осмотр подшипников

9. Преимущества

- Более высокая производительность (+10–50%)

- Лучшая классификация

- Меньшее энергопотребление

- Минимальное обслуживание

- Более длительный срок службы сита

- Точное разделение

10. Области применения вибросита CNC

- Обогащение полезных ископаемых

- Обогащение угля

- Строительные материалы

- Химическая промышленность

- Классификация тонкодисперсных материалов

- Обезвоживание

- Удаление шлама

Заключение

Вибросито CNC обеспечивает точное разделение материала. Мы предлагаем высокоэффективные сита для промышленных нужд. Правильная эксплуатация гарантирует наилучшие результаты. Регулярное техническое обслуживание продлевает срок службы оборудования.

Выберите нас, если вам нужны:

- Высокопроизводительное просеивание

- Энергоэффективная работа

- Низкие затраты на техническое обслуживание

- Длительный срок службы

- Превосходная классификация

Отзывы

Отзывов пока нет.